Ohtama Co., LTD. – Specializing in permalloy, magnetic shielding, magnetic field measurement, heat treatment and magnetic field cancellation.

Magnetic annealing & heat treatmentAnnealing

Ohtama’s magnetic annealing technologies

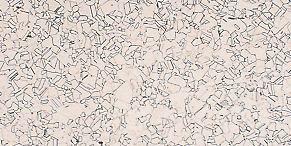

The magnetic properties of Permalloy are dramatically improved by heat treatment.The principle purpose of annealing is to homogenize the structure of the material and to soften it to make it more workable for machining and deformation processes. However the purpose of annealing Permalloy is to enhance its magnetic properties and eliminate or reduce residual stress following processing (pressing, welding, bending and cutting etc.).

Crystal grains Cross section of the material before heat treatment

Crystal grains Cross section of the material after heat treatment

Magnetic annealing to match specific materials and material properties

Based on years of experience, Ohtama provides an extensive range of heat treatment options to match specific materials and volume, making it possible to fully enhance the unique characteristics of varying manufacturers and materials.

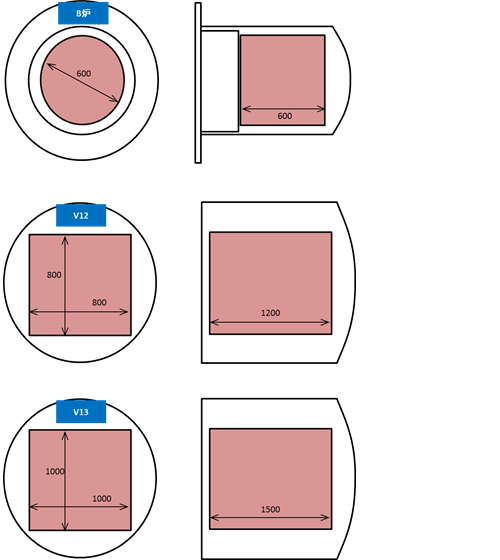

Vacuum furnace

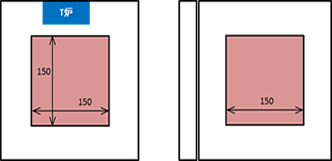

Ohtama boasts one of Japan’s largest dedicated magnetic annealing furnace (capacity: 1000 x 1000 x 1400 mm; 1 furnace).

A high vacuum is created within the furnace to which a small volume of hydrogen is supplied to achieve high-temperature heat treatment.

This furnace makes it possible to treat large products or a large volume of smaller products in one treatment.

| Vacuum furnace | 2 |

|---|

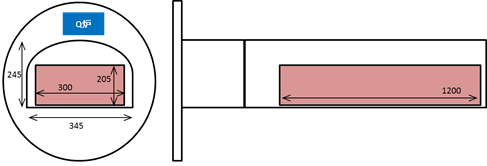

Hydrogen atmosphere furnace

Heat treatment in these furnaces is performed by suppling hydrogen to the furnace which has been heated to a high temperature.

| Type/Model | Name | Number |

|---|---|---|

| Bell Furnace | B Furnace | 2 |

| Horizontal Furnace | Q Furnace | 2 |

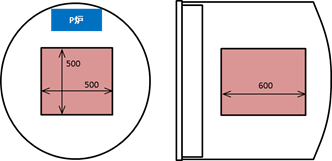

| Experimental Furnace | P Furnace, T Furnace | 2 |

Heat treatment furnaces

Experimental Furnace

Performance

| Vacuum furnace | Hydrogen atmosphere furnace (pot furnace, horizontal furnace, bell furnace) |

|

|---|---|---|

| Hydrogen purity | Dew point -60°C | Dew point -60°C |

| Temperature | -1200°C | -1100°C |

| Holding time | 2 hours - | 2 hours - |

| Inert gas | Nitrogen, Argon | Nitrogen |